MARKON MODULAR

MARKON MODULAR

Markon delivers professionally designed, constructed and installed modular housing solutions tailored to your needs. We partner with governments, local councils, private industry and individuals to accelerate sustainable, high‑quality responses to Australia’s housing crisis.

Scalable modular solutions for government, councils and industry.

Markon Modular delivers professionally designed, constructed and installed modular housing solutions tailored to your needs. We partner with governments, local councils, private industry and individuals to accelerate sustainable, high‑quality responses to Australia’s housing crisis.

We build modular solutions the way people actually live—comfortable, durable, and ready fast.

As part of The Markon Group and work hand‑in‑hand with our strategic partners to deliver modular accomadation solutions across Australia. Whether you’re from government, council, industry, or you’re an individual planning your next home, you’re in the right place.

What “Modular” means

(in plain English)

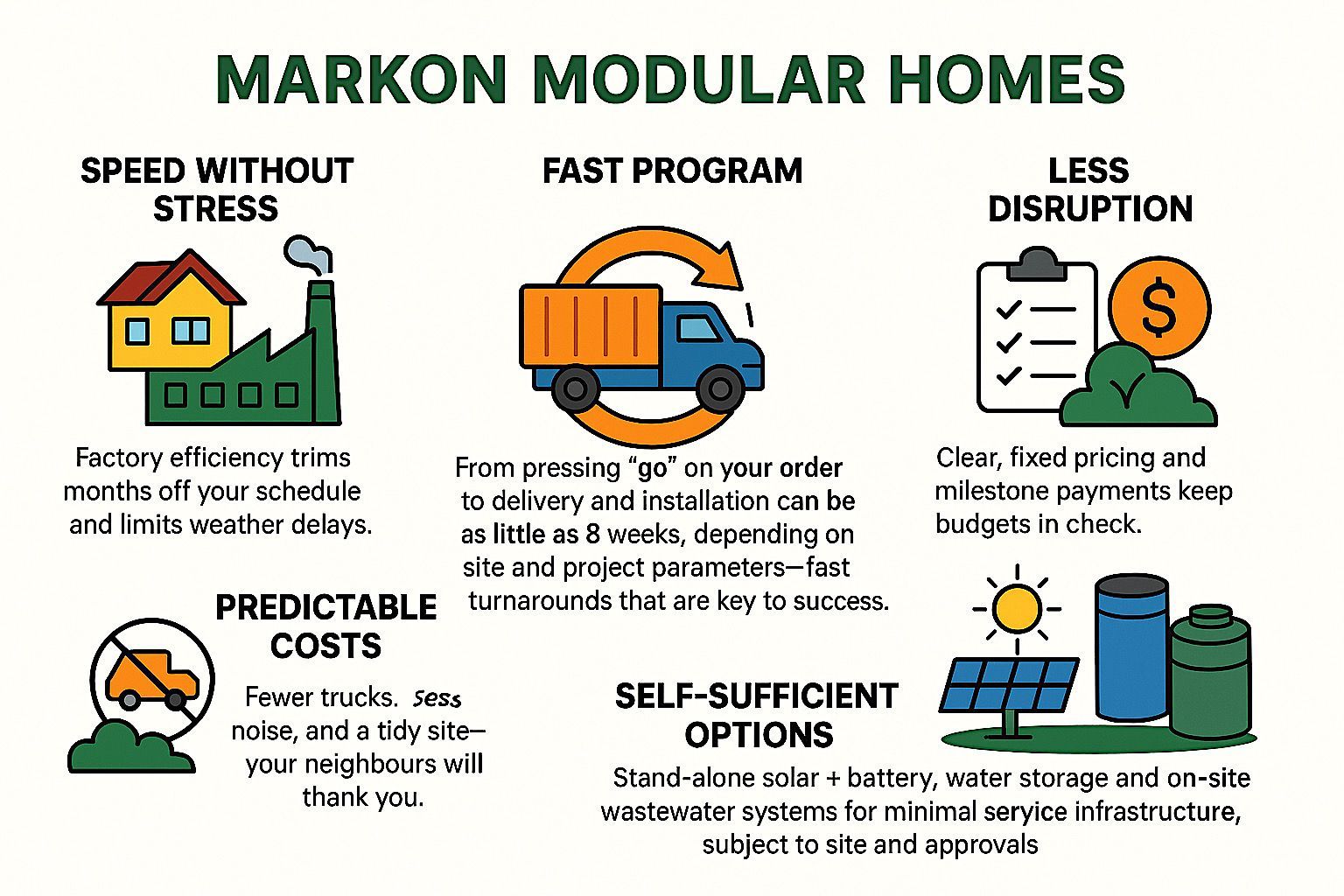

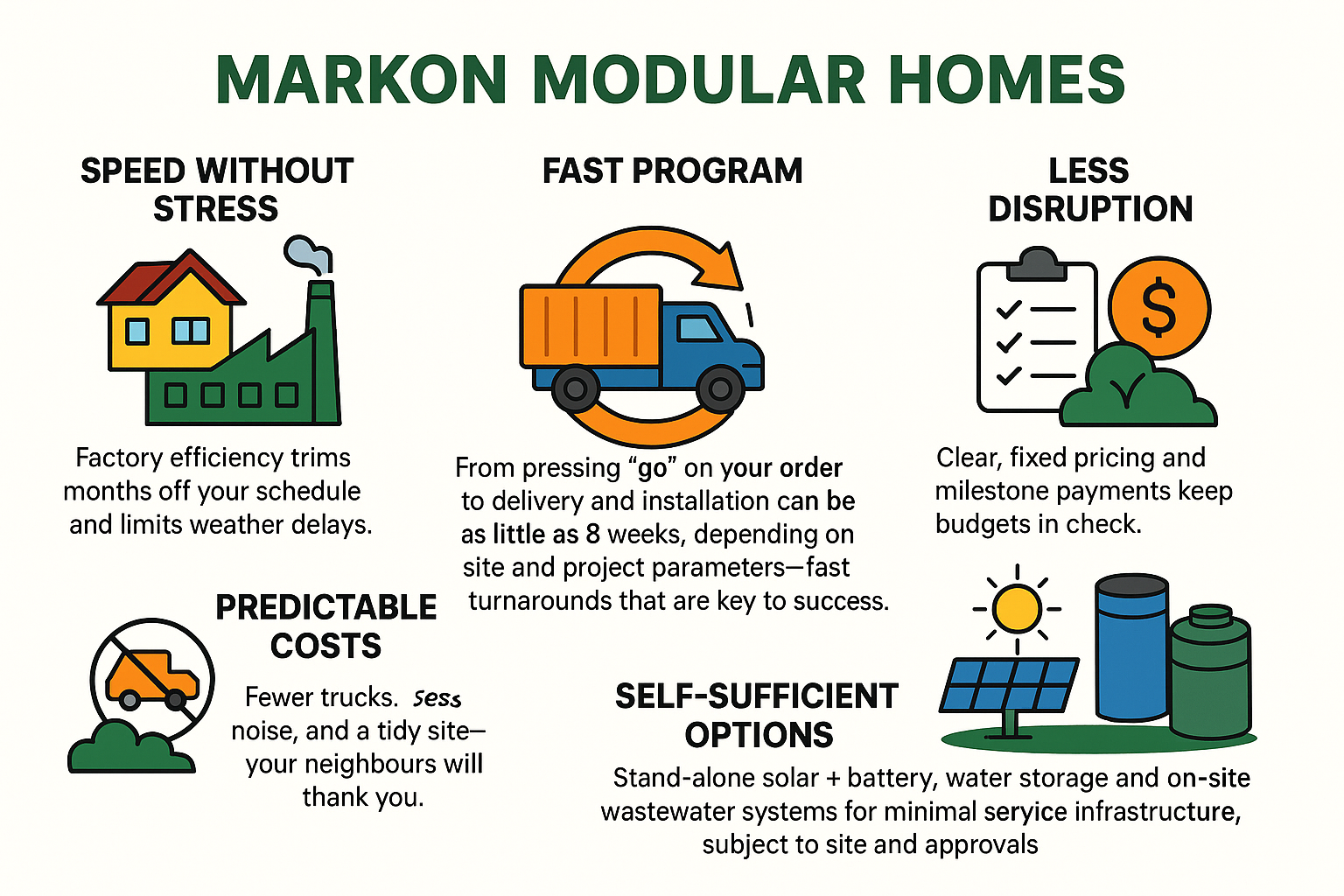

Most of your home is crafted in our climate‑controlled factory—think of it like building indoors where the weather can’t slow us down. We complete up to 75% off‑site, then deliver and “lock together” the modules on your land. On‑site work usually takes 2–3 weeks to connect services, finish details, and hand over the keys.

- Your modular solution is built by skilled craftsmen and trades, then assembled on‑site by our trained team of Australian tradies and builders who take pride in every detail.

- Built for decades. From engineered framing and durable roofing to premium composites and quality fixtures and finishes, every component is selected for longevity. We design to meet all relevant Australian Codes for your location.

- Quality you can feel. A controlled factory means safer work, fewer delays, and consistent quality from start to finish.

What “Modular” means

(in plain English)

Most of your home is crafted in our climate‑controlled factory—think of it like building indoors where the weather can’t slow us down. We complete up to 75% off‑site, then deliver and “lock together” the modules on your land. On‑site work usually takes 2–3 weeks to connect services, finish details, and hand over the keys.

- Your modular solution is built by skilled craftsmen and trades, then assembled on‑site by our trained team of Australian tradies and builders who take pride in every detail.

- Built for decades. From engineered framing and durable roofing to premium composites and quality fixtures and finishes, every component is selected for longevity. We design to meet all relevant Australian Codes for your location.

- Quality you can feel. A controlled factory means safer work, fewer delays, and consistent quality from start to finish.

What “modular” means (in plain English)

Most of your home is crafted in our climate‑controlled factory—think of it like building indoors where the weather can’t slow us down. We complete up to 75% off‑site, then deliver and “lock together” the modules on your land. On‑site work usually takes 2–3 weeks to connect services, finish details, and hand over the keys.

- Your modular solution is built by skilled craftsmen and trades, then assembled on‑site by our trained team of Australian tradies and builders who take pride in every detail.

- Built for decades. From engineered framing and durable roofing to premium composites and quality fixtures and finishes, every component is selected for longevity. We design to meet all relevant Australian Codes for your location.

- Quality you can feel. A controlled factory means safer work, fewer delays, and consistent quality from start to finish.

Homes near work change everything—recruitment, retention, and roster stability.

- Rapid deployment: Align staged handovers with hiring waves.

- Flexible layouts: Duplexes, studios, villages—configured for your workforce.

- Simple path: Site check → concept & pricing → factory build → set‑down → commissioning.

- Aftercare options: Maintenance plans that keep life simple.

Homes near work change everything—recruitment, retention, and roster stability.

- Rapid deployment: Align staged handovers with hiring waves.

- Flexible layouts: Duplexes, studios, villages—configured for your workforce.

- Simple path: Site check → concept & pricing → factory build → set‑down → commissioning.

- Aftercare options: Maintenance plans that keep life simple.

Remote indigenous

community housing

- Rapid housing solutions

- Self contained

- Weather and climate resistant

- Local labour installation with certified construction manager

Remote indigenous

community housing

- Rapid housing solutions

- Self contained

- Weather and climate resistant

- Local labour installation with certified construction manager

Remote indigenous

community housing

- Rapid housing solutions

- Self contained

- Weather and climate resistant

- Local labour installation with certified construction manager

Remote indigenous community housing

- Rapid housing solutions

- Self contained

- Weather and climate resistant

- Local labour installation with certified construction manager

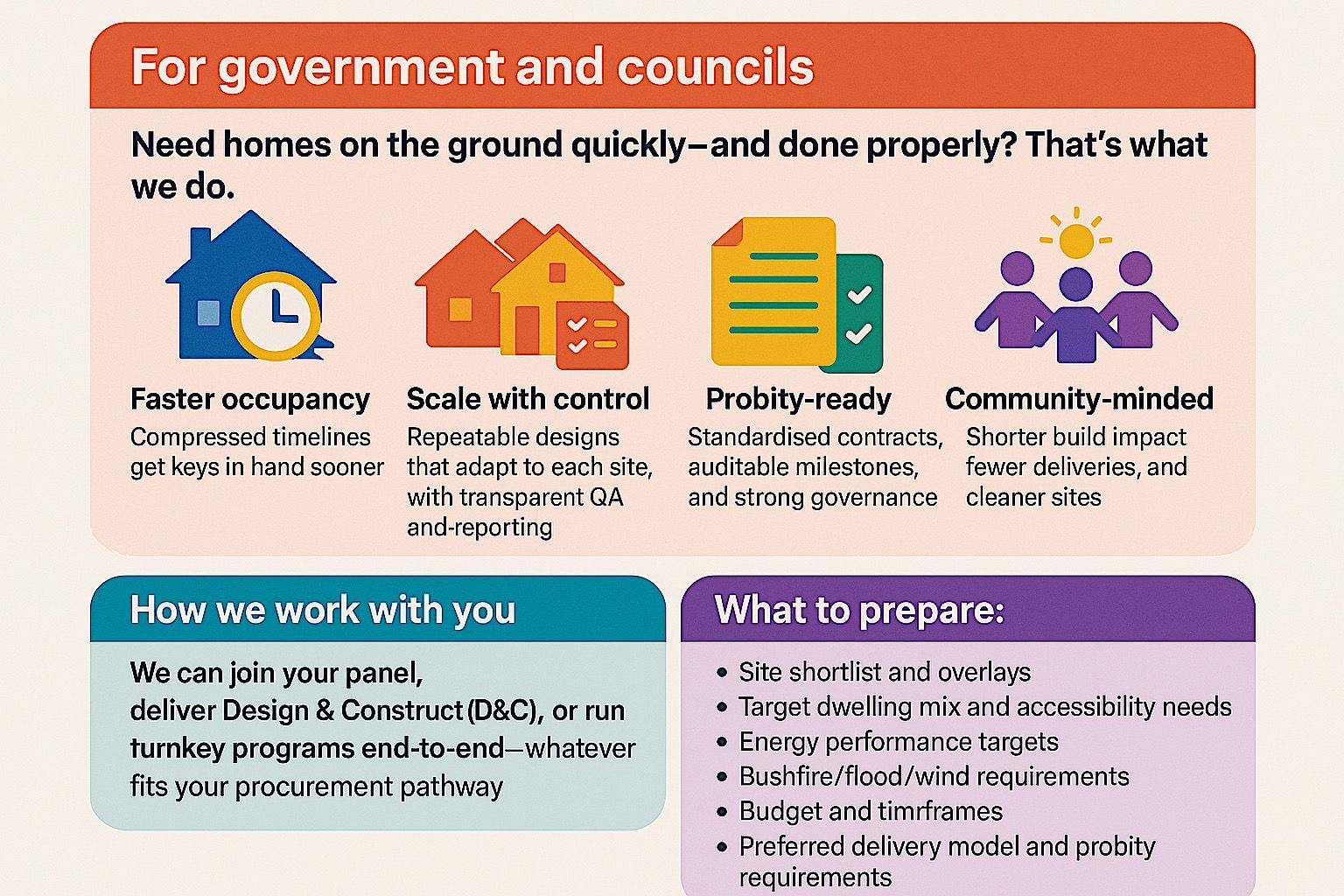

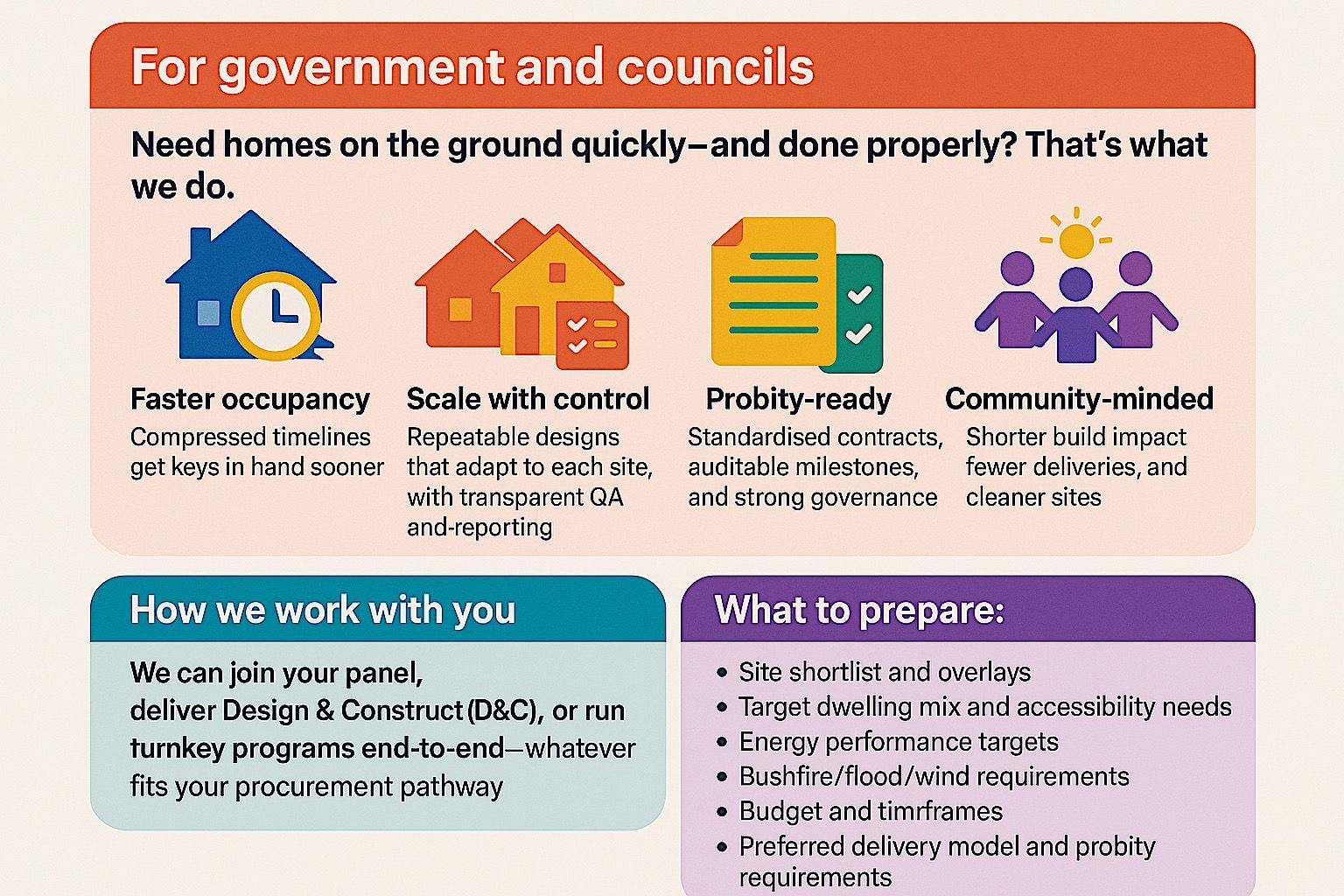

Modular Prefab Solutions for Public Housing Needs

- Our precision‑engineered modular homes empower state and local governments to turn housing policy into move‑in‑ready realities—fast.

- By manufacturing up to 75 % of each dwelling off‑site, we cut approval bottlenecks, site disruption and carbon footprints while guaranteeing consistent, code‑compliant quality.

- Units arrive fully finished, stackable and scalable, letting councils add emergency stock or entire neighbourhoods in weeks, not years.

- With predictable pricing, robust energy ratings and local‑supply‑chain job creation, our turnkey approach helps governments meet urgent housing targets and uplift communities simultaneously.

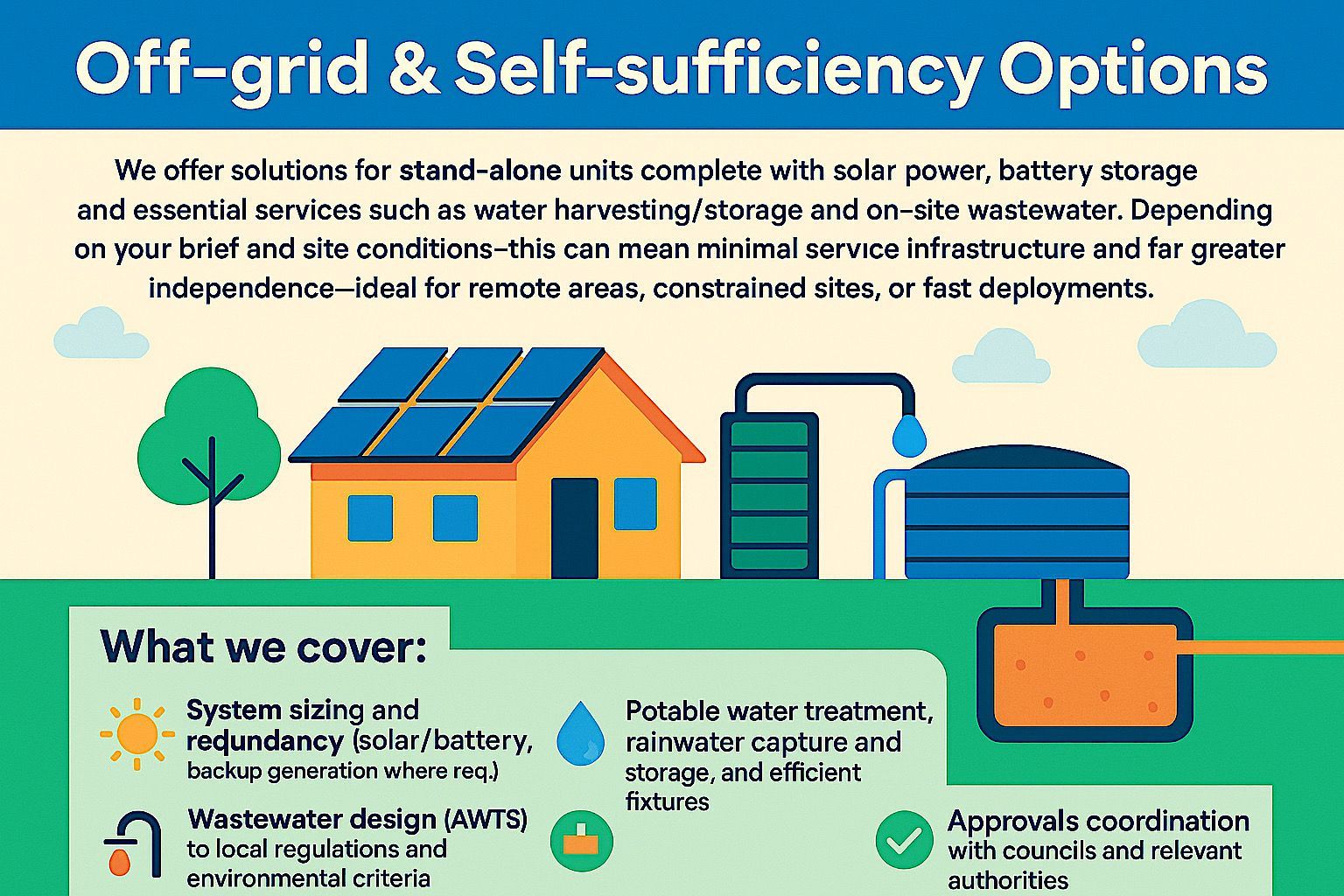

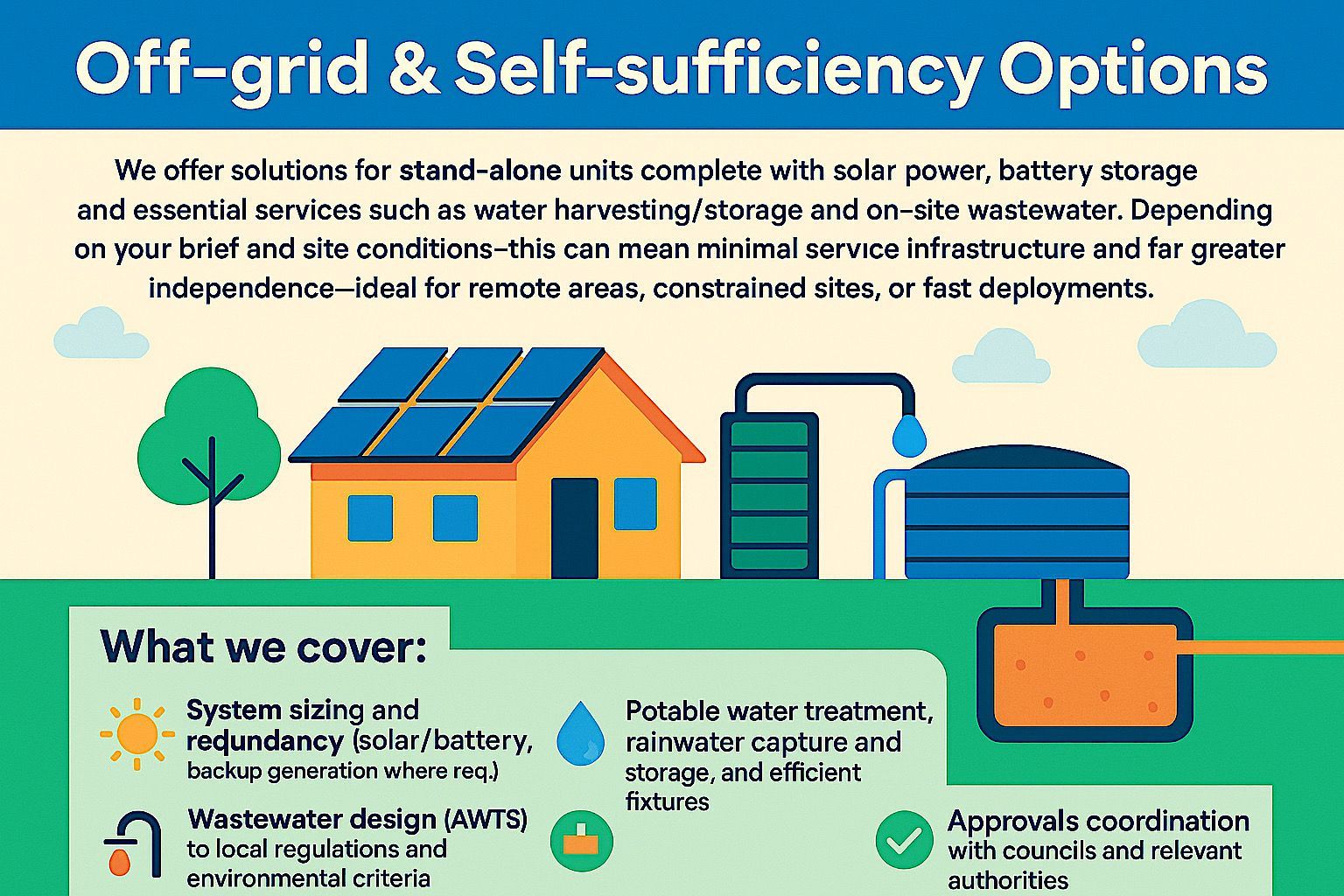

- Stand alone services such as LPG Gas, Solar Panels and Battery allow for ease of infractructre and rapid deployment.

Modular Prefab Solutions for Public Housing Needs

- Our precision‑engineered modular homes empower state and local governments to turn housing policy into move‑in‑ready realities—fast.

- By manufacturing up to 75 % of each dwelling off‑site, we cut approval bottlenecks, site disruption and carbon footprints while guaranteeing consistent, code‑compliant quality.

- Units arrive fully finished, stackable and scalable, letting councils add emergency stock or entire neighbourhoods in weeks, not years.

- With predictable pricing, robust energy ratings and local‑supply‑chain job creation, our turnkey approach helps governments meet urgent housing targets and uplift communities simultaneously.

- Stand alone services such as LPG Gas, Solar Panels and Battery allow for ease of infractructre and rapid deployment.

Need more than a handful of homes? Our program is built to scale—designed for 1,500+ units per year—so we can respond to community needs and employer demand without losing quality.

Procurement models that work

- Design & Construct (D&C) lump‑sum with fixed milestones.

- Panel or standing offer arrangements for multi‑site roll‑outs.

- Early Contractor Involvement (ECI) to accelerate approvals and value‑engineer for scale.

- Turnkey delivery for employers needing rapid workforce accommodation tied to HR outcomes.

Risk control & governance

- Factory QA records, ITPs and certificates at each stage.

- Standardised prefab contracts aligned to lender and government requirements.

- Program scheduling and logistics plans for remote and urban contexts.

- Clear HSE management, induction and site‑specific risk assessments.

Capacity when it counts

How financing modular works TODAY

(it’s easier than it used to be)

The old issue: Banks once struggled to fund off‑site work because security was tied to what existed on the land. That pushed buyers toward big upfront contributions or paying after installation.

What’s changed:

- Many mainstream lenders now allow progress payments during the factory build.

- Accredited manufacturers (like Markon, with Turnkey Housing) help unlock better LVRs and smoother drawdowns.

- Standard prefab contracts are speeding up approvals and reducing back‑and‑forth.

Reality check:

Some major banks still treat modular like “kit homes” and only release funds once the dwelling is on the land. Others are moving case‑by‑case—especially when there’s a fixed‑price contract and a proven manufacturer. Regional and non‑bank lenders are also offering modular‑specific packages.

Government incentives:

Policy is becoming method‑neutral (great news for modular). Where eligible, deposit assistance and guarantee schemes may apply, and green finance is growing for energy‑efficient homes.

How we help:

- Bank‑ready paperwork (fixed price, factory milestones, accreditations).

- We work with your broker or lender to match funding to the build program.

- Guidance for social/affordable, Indigenous, remote, and crisis housing pathways.

Disclaimer: General information only—please confirm details with your lender or a licensed broker.

TAGLINE HERE

The old issue: Banks once struggled to fund off‑site work because security was tied to what existed on the land. That pushed buyers toward big upfront contributions or paying after installation.

What’s changed:

- Many mainstream lenders now allow progress payments during the factory build.

- Accredited Builders (like The Markon Group) help unlock better LVRs and smoother drawdowns.

- Standard prefab contracts are speeding up approvals and reducing back‑and‑forth.

Reality check: Some major banks still treat modular like “kit homes” and only release funds once the dwelling is on the land. Others are moving case‑by‑case—especially when there’s a fixed‑price contract and a proven manufacturer. Regional and non‑bank lenders are also offering modular‑specific packages.

Government incentives: Policy is becoming method‑neutral (great news for modular). Where eligible, deposit assistance and guarantee schemes may apply, and green finance is growing for energy‑efficient homes.

How we help:

- Bank‑ready paperwork (fixed price, factory milestones, accreditations).

- We work with your broker or lender to match funding to the build program.

- Guidance for social/affordable, Indigenous, remote, and crisis housing pathways.

Disclaimer: General information only—please confirm details with your lender or a licensed broker.

How financing modular works now (it’s easier than it used to be)

Reality check:

Some major banks still treat modular like “kit homes” and only release funds once the dwelling is on the land. Others are moving case‑by‑case—especially when there’s a fixed‑price contract and a proven manufacturer. Regional and non‑bank lenders are also offering modular‑specific packages.

Government incentives:

Policy is becoming method‑neutral (great news for modular). Where eligible, deposit assistance and guarantee schemes may apply, and green finance is growing for energy‑efficient homes.

How we help:

- Bank‑ready paperwork (fixed price, factory milestones, accreditations).

- We work with your broker or lender to match funding to the build program.

- Guidance for social/affordable, Indigenous, remote, and crisis housing pathways.

Disclaimer: General information only—please confirm details with your lender or a licensed broker.

Environmental and social benefits

- Lower embodied and operational waste through material optimisation.

- Fewer deliveries to site and reduced neighbourhood disruption.

- Energy‑efficient envelope options to support “green” finance and lower running costs.

- Local employment of trades and apprentices in a safe, consistent factory setting.

Ready to talk?

Whether you’re planning a single home, a village, or a multi‑site program, we’ll make it clear and easy.

Next step: Please use the contact form at the end of this page and we’ll get back to you promptly.

We’d love to hear what you’re trying to achieve—and help you get there, faster.

Get in touch: Please use the contact form at the end of this page and we’ll respond promptly.

TAGLINE HERE

Need more than a handful of homes? Our program is built to scale—designed for 1,500+ units per year—so we can respond to community needs and employer demand without losing quality.

Procurement models that work

- Design & Construct (D&C) lump‑sum with fixed milestones.

- Panel or standing offer arrangements for multi‑site roll‑outs.

- Early Contractor Involvement (ECI) to accelerate approvals and value‑engineer for scale.

- Turnkey delivery for employers needing rapid workforce accommodation tied to HR outcomes.

Risk control & governance

- Factory QA records, ITPs and certificates at each stage.

- Standardised prefab contracts aligned to lender and government requirements.

- Program scheduling and logistics plans for remote and urban contexts.

- Clear HSE management, induction and site‑specific risk assessments.

Environmental and social benefits

- Lower embodied and operational waste through material optimisation.

- Fewer deliveries to site and reduced neighbourhood disruption.

- Energy‑efficient envelope options to support “green” finance and lower running costs.

- Local employment of trades and apprentices in a safe, consistent factory setting.

The simple 6‑step journey

- Listen & learn: Your goals, site, timeline, and budget.

- Concept & price: Options that fit—no surprises.

- Engineering & approvals: We navigate the paperwork with you.

- Factory build & QA: Craftsmen at work; every step documented.

- Delivery & set‑down: Transport, cranage, weather‑seal.

- Connect & handover: Services on, finishing touches done, keys to you.

Capacity when it counts

Ready to talk?

Whether you’re planning a single home, a village, or a multi‑site program, we’ll make it clear and easy.

Next step: Please use the contact form at the end of this page and we’ll get back to you promptly.

We’d love to hear what you’re trying to achieve—and help you get there, faster.

Get in touch: Please use the contact form at the end of this page and we’ll respond promptly.