Build a Better Home with TRUECORE® Steel

TRUECORE STEEL – OUR PREFERRED FRAMING PARTNER

At The Markon Group, we are committed to using only the highest quality materials to build homes that last a lifetime. That's why we've partnered with TRUECORE® steel to offer our clients a framing solution that is not only stronger and more durable but also perfectly suited to the unique challenges of the Queensland climate.

Building in Southeast Queensland presents unique challenges that demand superior building materials. From the ever-present threat of termites to the region's high humidity, intense heat, and seasonal weather extremes, your home's structural integrity depends on choosing the right framing system. Traditional treated pine timber has served the industry for decades, but modern building science and materials engineering have given us something better—TRUECORE® steel framing.

With TRUECORE® steel, you can build with the absolute confidence that your home's frame will remain straight, true, and dimensionally stable for generations. You'll have complete peace of mind knowing that termites can never compromise your home's structural integrity, and you'll benefit from a framing system that's engineered with such precision that your home will be built to tolerances impossible to achieve with natural timber.

A Partnership Built on Quality and Trust

Our commitment to excellence extends beyond craftsmanship—it starts with choosing the right building materials from partners who share our values

Why We Partner with TRUECORE®

The Markon Group chooses to build exclusively with TRUECORE® steel because it aligns perfectly with our unwavering commitment to excellence, durability, and client satisfaction. After extensive research and years of practical experience in the Southeast Queensland building market, we've concluded that TRUECORE® steel framing represents the gold standard in residential construction—a framing system that outperforms traditional timber in virtually every meaningful metric.

Manufactured by BlueScope, a name synonymous with Australian steel innovation and quality, TRUECORE® is the result of over a century of metallurgical expertise and continuous improvement. BlueScope is not just any steel manufacturer—they're Australia's largest steel producer and one of the world's most respected names in coated and painted steel products. Their reputation has been built on rigorous quality control, cutting-edge manufacturing processes, and an uncompromising commitment to producing steel that performs in Australia's harsh and varied climate conditions.

TRUECORE® offers a level of precision, consistency, and durability that traditional timber frames simply cannot match. Every TRUECORE® steel stud and frame member is manufactured to exacting tolerances in state-of-the-art facilities, ensuring dimensional accuracy that's measured in fractions of a millimetre. This level of precision translates directly to better building outcomes—straighter walls, perfectly aligned door and window frames, and a finished home that meets the highest standards of quality. This partnership allows us to provide our clients with a superior home that is not only built to last but also designed to accommodate the open-plan living spaces and architectural features that define modern Australian living.

Australian Made, Australian Tested

One of the most compelling reasons we've chosen TRUECORE® is that it's genuinely Australian made. In an era where many building materials are imported from overseas with questionable quality control and uncertain provenance, TRUECORE® steel is manufactured right here in Australia, specifically engineered and tested for Australian conditions.

BlueScope's manufacturing facilities in New South Wales and Victoria produce steel that's designed to withstand our unique environmental challenges—from the tropical humidity of Queensland to the bushfire-prone regions of the southeast.

The TRUECORE® manufacturing process incorporates advanced galvanising technology that provides exceptional corrosion resistance. The steel is coated with a zinc-aluminium alloy (Zincalume® or Galvanised) that forms a protective barrier against moisture, salt air (particularly important for coastal Queensland properties), and atmospheric pollutants. This isn't a surface treatment that can wear off—it's a metallurgically bonded coating that becomes an integral part of the steel itself, providing protection that lasts for decades.

Furthermore, BlueScope subjects every batch of TRUECORE® steel to rigorous testing protocols that verify its mechanical properties, coating thickness, dimensional accuracy, and structural performance. These aren't token quality checks—they're comprehensive testing regimes that ensure every piece of steel that arrives on our building sites meets or exceeds Australian Standards.

When we frame your home with TRUECORE®, we're not making compromises or hoping for the best—we're working with a material that's been proven through decades of real-world performance and scientific testing.

What Sets TRUECORE® Apart

Superior Corrosion Protection

TRUECORE®'s advanced metallic coating system provides up to 4 times the corrosion resistance of standard galvanised steel, ensuring your frame stays structurally sound even in Queensland's humid coastal environment.

Engineered Consistency

Unlike timber, which varies in density, moisture content, and structural properties from one piece to another, every TRUECORE® member is manufactured to identical specifications—no surprises, no variations.

High Strength-to-Weight Ratio

TRUECORE® steel delivers exceptional structural strength without the weight penalty. This means we can create larger open-plan spaces, wider spans, and more flexible floor plans without compromising structural integrity.

Backed by BlueScope's Reputation

With over 100 years of steel-making expertise and a 50-year warranty, BlueScope stands behind TRUECORE® with one of the most comprehensive guarantees in the building industry.

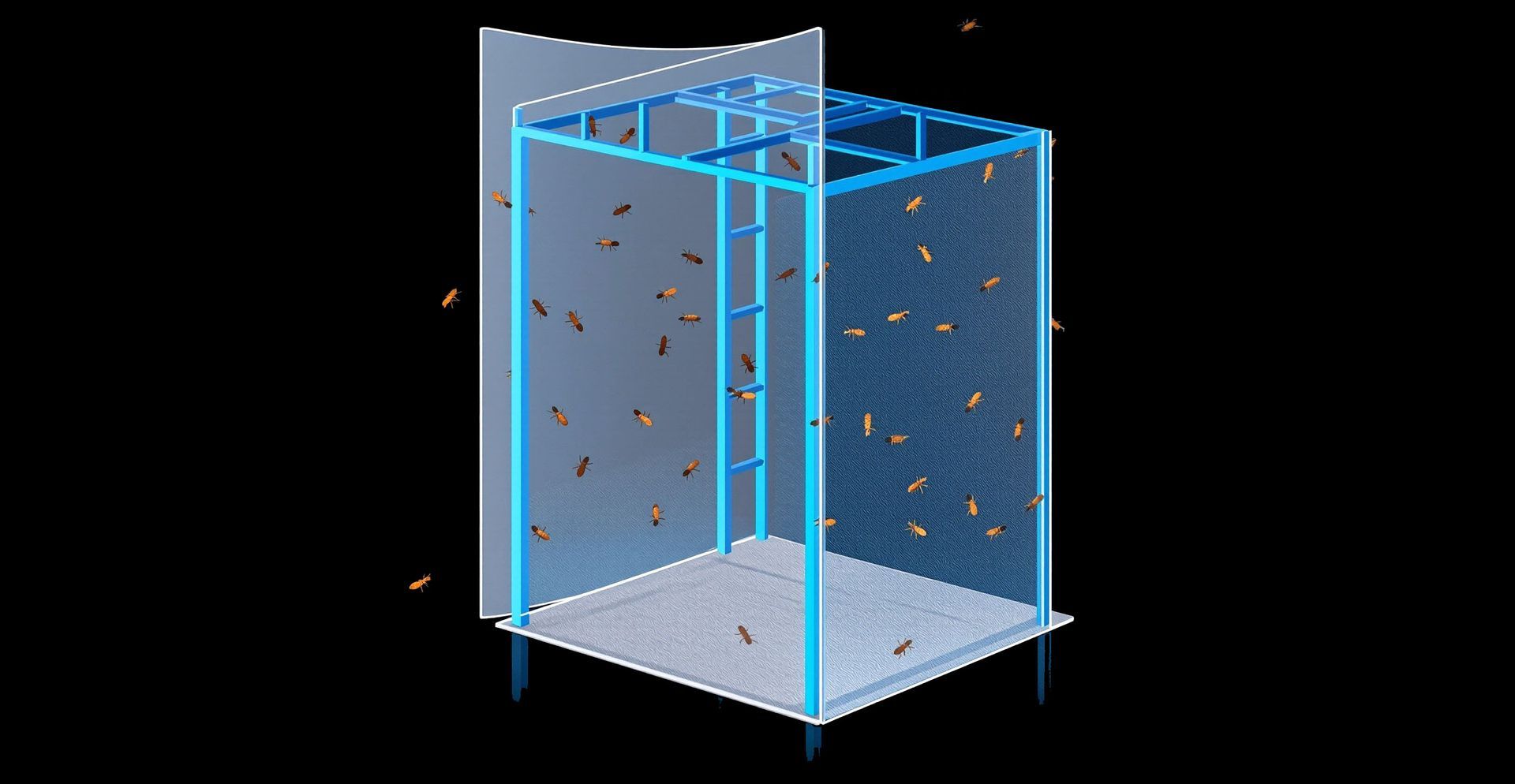

100% Termite Proof

In Southeast Queensland, termites represent one of the most serious and expensive threats to residential construction. These destructive insects cause hundreds of millions of dollars in damage to Australian homes every year, and the subtropical climate of Brisbane and the surrounding regions provides ideal conditions for termite activity year-round.

Traditional timber framing is highly vulnerable to termite attack, and even treated pine can be compromised if the chemical treatment degrades over time or if termites find untreated sections. TRUECORE® steel is 100% termite and borer proof—not resistant, but completely immune. Termites simply cannot consume or damage steel, which means your home's structural integrity can never be compromised by these pests.

This eliminates the need for ongoing chemical barrier treatments, termite inspections every 12 months, and the constant worry that termites might be silently destroying your home's frame. With TRUECORE® steel, you gain complete peace of mind knowing that your most significant investment is protected from one of Queensland's most persistent threats.

Straight & True for Life

One of the most common problems with timber-framed homes is dimensional instability over time. Timber is a natural, organic material that responds to changes in temperature and humidity by expanding, contracting, warping, twisting, and bowing.

This is particularly problematic in Queensland where we experience high humidity, significant seasonal temperature variations, and occasional dramatic weather events. As timber frames move and distort, doors begin to stick, windows become difficult to open or close, cracks appear in walls and ceilings, and the entire structure can gradually become out of square.

These aren't just cosmetic issues—they're symptoms of structural movement that can compromise your home's integrity and lead to expensive repairs. TRUECORE® steel frames are dimensionally stable for the life of your home. Steel doesn't warp, twist, bow, or shrink.

The frame we install during construction will maintain its precise geometry and alignment for decades. This means your windows and doors will operate smoothly throughout your home's lifetime, your walls will remain perfectly straight and true, and you won't experience the gradual deterioration in fit and finish that plagues timber-framed homes.

The result is a home that looks and performs like new even after 20, 30, or 50 years of occupation.

Design Flexibility

Modern Australian families want open-plan living spaces that seamlessly connect kitchen, dining, and living areas, creating bright, airy environments perfect for entertaining and family life. They want high ceilings that add volume and grandeur, large windows and sliding doors that blur the boundary between indoor and outdoor spaces, and floor plans that can adapt to changing needs over time.

Many of these design features are difficult or impossible to achieve with traditional timber framing because timber has limitations in terms of span capacity and load-bearing capability. TRUECORE® steel's exceptional strength-to-weight ratio changes everything. Steel's superior structural properties allow us to create longer spans between load-bearing walls, eliminating the need for intermediate supports that would interrupt open-plan spaces.

We can accommodate larger window and door openings without compromising structural integrity. We can design higher ceilings, incorporate mezzanine levels, and create dramatic architectural features that would be impractical with timber.

This design flexibility doesn't just make your home more beautiful and functional—it also provides future-proofing. If you want to renovate or reconfigure your home's layout in the future, steel framing provides far more options than timber because the structure is stronger and more adaptable to changes.

Backed by a 50-Year Warranty

When you invest hundreds of thousands of dollars in building a new home, you need absolute confidence that the materials and workmanship will stand the test of time. TRUECORE® steel is backed by BlueScope's comprehensive 50-year warranty for residential applications—one of the most extensive guarantees available in the Australian building industry.

This isn't a limited warranty with pages of exclusions and conditions designed to avoid paying claims. It's a genuine commitment from BlueScope, backed by over a century of steel manufacturing expertise and a reputation for standing behind their products. The warranty covers structural performance, corrosion resistance, and the integrity of the protective coating system, giving you peace of mind that your home's frame will maintain its strength and appearance for half a century.

This warranty reflects BlueScope's absolute confidence in TRUECORE® steel based on decades of real-world performance data, accelerated aging tests, and corrosion testing in harsh Australian environments.

It's a testament to the exceptional quality and durability of TRUECORE® steel, and it provides you with financial protection and assurance that few other building materials can match. When The Markon Group builds your home with TRUECORE® steel, you're not just getting a superior framing system—you're getting the backing of Australia's most respected steel manufacturer and a warranty that protects your investment for generations.

Steel vs. Timber: The Clear Choice for Queensland

When it comes to building in Southeast Queensland, steel framing offers better long-term outcomes than treated pine

Superior Durability & Longevity

When we compare steel frames to treated pine timber on durability metrics, steel frames are the undisputed winner. TRUECORE® steel is resistant to rot, decay, fungal growth, and insect damage—problems that continually plague timber frames in Queensland's humid climate. Steel doesn't absorb moisture, so it can't rot or develop mould. It won't be consumed by borers, termites, or other wood-destroying insects. And unlike timber, which can degrade when exposed to UV radiation and weathering during construction, steel maintains its structural properties even with temporary exposure to the elements. The result is a framing system that will maintain its strength and integrity for the entire design life of your home—typically 50+ years—without the gradual deterioration that affects timber frames. This superior durability means lower maintenance costs, fewer repairs, and better long-term value for your investment.

Fire Safety & Insurance Benefits

In an era where bushfire risk is an increasing concern for Queensland homeowners, the fire performance of your home's frame matters more than ever. TRUECORE® steel is non-combustible—it won't catch fire, burn, or contribute fuel to a fire. While timber frames will ignite and burn in a house fire or bushfire scenario, steel frames remain structurally intact far longer, providing crucial extra time for occupants to escape and for firefighters to control the blaze. Many insurance companies recognise this superior fire resistance and offer reduced premiums for steel-framed homes, particularly in bushfire-prone areas. Beyond the insurance benefits, the fire safety of steel framing provides invaluable peace of mind—you're building a home that's inherently safer for your family in the worst-case scenario.

Zero Termite Risk

Termites are responsible for more than $1 billion in damage to Australian homes every year, and Southeast Queensland's warm, humid climate creates ideal conditions for termite colonies to thrive year-round. With a traditional timber frame, you're constantly at risk of termite attack, despite chemical barriers, treated timber, and regular inspections. The harsh reality is that no timber frame can be considered 100% safe from termites—the chemical treatments degrade over time, barriers can be breached, and termites are remarkably persistent in finding vulnerabilities. With TRUECORE® steel, this risk is completely eliminated. Termites simply cannot eat or damage steel, which means your home's structural integrity can never be compromised by these destructive pests. This isn't just about avoiding repair costs—it's about protecting your family's safety and your most significant financial investment from one of Queensland's most serious threats to residential construction.

Precision Engineering & Build Quality

Timber is a natural material, which means every piece of timber has natural variations in density, moisture content, strength, straightness, and structural properties. Some timber studs might have knots or splits that weaken them. Some might be slightly bowed or twisted even when new. Some might have higher moisture content than others, leading to unpredictable movement as they dry out in your home. This inherent variability makes it impossible to achieve the level of precision and consistency that modern construction demands. TRUECORE® steel is different. Every steel stud, nogging, and frame member is manufactured to identical specifications with dimensional tolerances measured in fractions of a millimetre. There's no variation from one piece to another—the first stud off the production line is identical to the ten-thousandth. This precision engineering translates directly to superior build quality. Walls are straighter, corners are squarer, and every component fits together with precision. The result is a home that's built to tighter tolerances, with fewer defects, better finishes, and superior overall quality.

Environmental Sustainability

If environmental responsibility matters to you, steel framing has significant advantages over timber. TRUECORE® steel is 100% recyclable—not just theoretically recyclable, but actively and routinely recycled at the end of a building's life. Steel can be recycled indefinitely without losing its properties, and Australia has well-established steel recycling infrastructure. In fact, BlueScope's steel production already incorporates significant recycled content. Compare this to treated pine timber, which cannot be recycled after use because of the chemical treatments it contains. Treated timber typically ends up in landfill at end-of-life, where the preservative chemicals can potentially leach into soil and groundwater. Additionally, steel framing produces very little waste during construction—the frames are prefabricated to exact dimensions, so there's minimal offcut waste. Timber framing, by contrast, generates substantial waste from cutting, fitting, and discarding unusable pieces. When you choose TRUECORE® steel, you're making an environmentally responsible choice that reduces waste, conserves resources, and supports a circular economy.

Moisture Resistance & Mould Prevention

Queensland's subtropical climate means high humidity levels for much of the year, and this moisture in the air can cause serious problems for timber frames. Timber absorbs moisture from the atmosphere, which can lead to swelling, warping, and dimensional changes. More seriously, sustained high moisture content in timber creates ideal conditions for mould and fungal growth, which can compromise the timber's structural integrity and create health hazards for occupants. Steel doesn't absorb moisture, so these problems simply don't occur. A steel frame maintains its dimensions and structural properties regardless of humidity levels, and steel provides no food source for mould or fungus. This moisture resistance is particularly important during the construction phase—timber frames can absorb significant moisture if exposed to rain before the building is weatherproof, leading to problems that might not become apparent for years. Steel frames are unaffected by weather exposure during construction, ensuring the frame you move into is exactly as strong and straight as when it was installed.

What TRUECORE® Steel Means for Your Home

Moving beyond technical specifications—here's how TRUECORE® steel framing translates into real, tangible benefits for you and your family

A Home That Stays Perfect, Year After Year

When you build with TRUECORE® steel, you're building a home that will look and perform like new even after decades of occupation. Your doors will open and close smoothly. Your windows will slide effortlessly on their tracks. Your walls will remain perfectly straight and true, with no cracks appearing in cornices or plaster. Your architraves and skirting boards will maintain their tight, professional fit against walls that don't move or shift.

This isn't just about aesthetics—it's about living in a home that maintains its quality and finish throughout your family's lifetime. You won't experience the gradual deterioration in fit and finish that characterises timber-framed homes as the frame warps, twists, and settles over time. The home you move into is the home you'll enjoy for decades, with no compromise in quality or performance.

Lower Total Cost of Ownership

While the initial investment in steel framing may be slightly higher than timber, your lifetime cost of ownership will be significantly lower. You'll save thousands of dollars over the life of your home by eliminating termite inspection fees, termite barrier renewals, and the risk of expensive termite damage repairs that can cost $20,000 to $100,000+ in severe cases.

You'll avoid the costs of repairing sticking doors and windows, fixing cracks in walls and ceilings caused by frame movement, and adjusting or replacing components that no longer fit properly due to structural settlement. Many insurance companies recognise steel framing's superior fire resistance and offer premium discounts. Your steel-framed home will also command a premium in the resale market because buyers understand the value of maintenance-free, termite-proof construction.

Complete Freedom from Pest Worries

For Queensland homeowners, termites represent a constant source of anxiety. With traditional timber framing, you live with the knowledge that termites might be silently destroying your home's structure, despite your best prevention efforts. Annual termite inspections are expensive and stressful—every inspection brings the worry that this might be the year termites are discovered. And if termites are found, you face expensive treatment costs, potential structural repairs, and the disruption of having your home treated with chemicals.

With TRUECORE® steel framing, all of this anxiety simply disappears. Termites cannot eat, damage, or compromise steel. Your home's structural integrity is permanently protected from pest damage. You'll never need annual termite inspections of your frame. You'll never face the nightmare scenario of discovering severe termite damage that requires tens of thousands of dollars in repairs. You can simply enjoy your home without this constant background worry that plagues owners of timber-framed homes in Queensland.

Superior Resale Value and Market Appeal

When it comes time to sell your home, TRUECORE® steel framing becomes a powerful marketing advantage. Educated buyers—particularly those who've experienced termite problems or structural issues in previous homes—actively seek out steel-framed properties because they understand the long-term value proposition. Real estate agents can highlight your home's steel frame as a premium feature that sets it apart from competing properties.

Steel framing provides tangible evidence that your home was built to a higher standard with better materials, which translates to higher sale prices and faster sales. Buyers appreciate knowing they won't inherit ongoing termite inspection costs, won't face potential termite repair bills, and won't experience the problems with sticking doors, cracked walls, and structural movement that are common in older timber-framed homes. In Queensland's competitive property market, steel framing can be the feature that makes your home stand out and commands a premium price.

Superior Resale Value and Market Appeal

When it comes time to sell your home, TRUECORE® steel framing becomes a powerful marketing advantage. Educated buyers—particularly those who've experienced termite problems or structural issues in previous homes—actively seek out steel-framed properties because they understand the long-term value proposition. Real estate agents can highlight your home's steel frame as a premium feature that sets it apart from competing properties.

Steel framing provides tangible evidence that your home was built to a higher standard with better materials, which translates to higher sale prices and faster sales. Buyers appreciate knowing they won't inherit ongoing termite inspection costs, won't face potential termite repair bills, and won't experience the problems with sticking doors, cracked walls, and structural movement that are common in older timber-framed homes. In Queensland's competitive property market, steel framing can be the feature that makes your home stand out and commands a premium price.

An Environmentally Responsible Choice

If sustainability matters to your family, TRUECORE® steel offers clear environmental advantages. The steel is 100% recyclable and is routinely recycled at the end of a building's life without loss of properties—it can be recycled infinitely. BlueScope's steel production already incorporates significant recycled content, and Australia has well-established steel recycling infrastructure that ensures end-of-life steel is recovered and reused.

Compare this to treated timber, which cannot be recycled due to its chemical preservatives and typically ends up in landfill, where those chemicals can potentially leach into soil and water. Steel framing also produces minimal waste during construction because frames are prefabricated to exact dimensions. By choosing steel, you're making a choice that supports circular economy principles, reduces waste, and ensures that the materials in your home's frame can be fully recovered and reused at the end of the building's service life—a legacy you can feel good about.

Frequently Asked Questions

Is steel framing more expensive than timber framing ?

This is probably the most common question we receive about steel framing, and it's important to understand both the initial costs and the long-term value proposition.

Yes, the upfront material cost of TRUECORE® steel framing can be 10-20% higher than treated pine timber framing, depending on the specific design of your home. However, this initial cost difference needs to be considered in the context of total cost of ownership over the life of your home—typically 50+ years.

Steel framing eliminates the need for expensive chemical termite barriers (saving $2,000-$5,000 initially), ongoing annual termite inspections (saving $200-$300 per year), and potential termite treatment or structural repairs (which can cost $10,000 to $100,000+ if termites are discovered). Steel's dimensional stability means you'll avoid the costs associated with doors and windows that stick due to frame movement, cracks in walls and ceilings, and eventual structural repairs.

Many insurance companies offer reduced premiums for steel-framed homes due to their superior fire resistance, providing ongoing savings. When you factor in these long-term savings, superior durability, and better resale value, steel framing is actually the more cost-effective choice for most homeowners.

You're not just buying a framing system—you're investing in decades of maintenance-free structural performance and peace of mind.

How does steel framing perform in terms of energy efficiency and thermal insulation?

This is another frequently asked question, and it reflects a common concern about steel's high thermal conductivity.

It's true that steel is an excellent conductor of heat—far better than timber—which creates what engineers call "thermal bridging" where heat can transfer through the steel frame members. However, this doesn't mean steel-framed homes are less energy-efficient.

Modern building practices have developed effective strategies to eliminate thermal bridging and ensure steel-framed homes perform just as well as or better than timber-framed homes in terms of energy efficiency.

At The Markon Group, we use advanced insulation systems that include thermal breaks between the steel frame and the wall linings. These thermal breaks are typically foam or fibre-based materials that interrupt the thermal pathway through the steel. We also use high-performance bulk insulation (such as polyester or glasswool batts) in the wall cavities and reflective foil insulation on the exterior of the frame.

When properly designed and installed, these insulation systems ensure that steel-framed homes easily meet or exceed the energy efficiency requirements of the National Construction Code (NCC). In fact, the precision and consistency of steel framing actually helps us achieve better insulation performance because there are no gaps, splits, or irregularities in the frame where insulation might be compressed or gaps might occur.

Your steel-framed home will be comfortable year-round, with lower heating and cooling costs than comparable timber-framed homes.

Will I hear noises from a steel-framed house - creaking, popping, or expansion sounds?

This is a common misconception about steel framing that we want to address directly and honestly.

Yes, steel does expand and contract slightly in response to temperature changes—this is a physical property of all materials, including timber. However, the amount of thermal movement in steel is actually quite small, and modern construction techniques effectively eliminate any noise associated with this movement.

The key is proper installation. When steel frames are correctly fixed to the foundation and structure, with appropriate expansion joints and fastening methods, there is no audible movement or noise.

At The Markon Group, our installers are trained specifically in steel frame installation best practices, including the proper use of fasteners, connection methods, and expansion provisions that prevent noise. In fact, many of the "noises" that homeowners attribute to framing are actually caused by other factors—roof trusses expanding and contracting, house settling on foundations, or timber flooring moving—and these occur in both timber and steel-framed homes.

We've built a significant quantity of steel-framed homes in Southeast Queensland, and noise has never been a reported issue from our clients. When you visit completed Markon Group homes or speak to our past clients, you'll find that steel-framed homes are quiet, comfortable, and indistinguishable from timber-framed homes in terms of everyday living experience.

How long does it take to build with steel framing compared to timber?

One of the often-overlooked advantages of steel framing is its positive impact on construction timelines.

TRUECORE® steel frames are prefabricated in controlled factory conditions using precise engineering data from your approved plans.

This means that when the frame arrives on site, every member is cut to exact length, all holes for services (plumbing, electrical) are pre-punched, and the frame can be erected quickly and efficiently.

A typical residential steel frame can be erected in 2-3 days, compared to 5-7 days for a comparable timber frame that requires on-site cutting, fitting, and adjustment. The precision of steel framing also means fewer problems and delays during subsequent trades.

When walls are perfectly straight and square, installers of windows, doors, cladding, and internal linings can work more efficiently with fewer problems and delays.

There's no waiting for wet timber to dry out, no discovery of twisted or bowed studs that need to be replaced, and no structural problems that require engineer review and redesign.

While the overall construction timeline depends on many factors beyond just framing, most steel-framed homes can be completed 2-4 weeks faster than equivalent timber-framed homes.

This means you can move into your new home sooner, and you'll save money on construction financing and temporary accommodation costs during the build.

What is the warranty coverageTRUECORE® steel frames?

TRUECORE® steel is backed by BlueScope's comprehensive 50-year warranty for residential applications when the steel is used in accordance with their published guidelines and Australian Standards.

This warranty covers the structural performance of the steel itself and the integrity of the protective coating system (galvanised or Zincalume®) against perforation due to corrosion.

This is one of the longest and most comprehensive warranties available in the Australian building industry—far exceeding the typical warranties offered for treated timber framing.

The warranty is backed by BlueScope, a company with over 100 years of steel manufacturing expertise and an excellent reputation for standing behind their products. It's important to understand that this warranty reflects BlueScope's confidence in TRUECORE® steel based on decades of real-world performance data and extensive corrosion testing in harsh Australian environments. The 50-year period isn't arbitrary—it's based on scientific evidence that TRUECORE® steel will maintain its structural integrity and corrosion resistance for at least this long when properly installed and maintained.

For you as a homeowner, this warranty provides both peace of mind and financial protection. If there were ever a structural failure or corrosion perforation of your steel frame within the 50-year warranty period (which is extremely unlikely), BlueScope will take responsibility for remedying the problem.

This level of protection is simply not available with timber framing, where warranties are typically limited to manufacturing defects and don't cover natural deterioration, pest damage, or dimensional changes.

Can I hang heavy items like cabinets

This is an excellent practical question that many homeowners ask, and the answer is absolutely yes—in fact, it's often easier and more secure to fix heavy items to steel frames than to timber frames.

TRUECORE® steel studs provide excellent fixing points for all types of wall-mounted items, from kitchen cabinets and bathroom vanities to large flatscreen TVs and heavy artwork. The key is using the right fixings for the application. For heavy items, we use self-drilling screws that are specifically designed for steel framing.

These screws have a drill point that easily penetrates the steel and creates a strong, secure connection. The steel itself is much stronger than timber, so the fixing points won't pull out or weaken over time the way timber can.

For extremely heavy items like large kitchen cabinets or stone benchtops, we can specify the location of extra steel studs or noggins during the design phase to ensure there's adequate support exactly where you need it. Many homeowners who have lived in both timber and steel-framed homes actually prefer steel because the fixing points are more predictable (steel studs are typically spaced at exactly 450mm or 600mm centres, unlike timber which can vary) and more secure.

We provide all our clients with a frame plan that shows the exact location of every stud and nogging, making it easy to locate fixing points for future renovations or installations.

You'll have no problems hanging anything you want on your steel-framed walls—the structure is more than capable of supporting typical and even exceptional residential loads.

How does steel framing handle the high humidity and coastal conditions in South East Queensland?

This question is particularly relevant for Southeast Queensland homeowners, especially those building near the coast where salt-laden air can accelerate corrosion of metal components.

TRUECORE® steel is specifically engineered and tested for Australian coastal conditions, making it an ideal choice for Queensland's subtropical climate. The steel is protected by a metallurgically bonded coating of zinc-aluminium alloy (either Galvanised or Zincalume®) that provides exceptional corrosion resistance even in harsh coastal environments.

This isn't a paint or surface treatment that can chip or wear off—it's an integral part of the steel that's applied during the manufacturing process at high temperatures, creating a protective barrier that bonds at the molecular level to the steel substrate.

BlueScope conducts extensive corrosion testing on TRUECORE® steel in real-world coastal environments, and the results demonstrate excellent performance even in severe exposure conditions. Unlike timber, which readily absorbs moisture from Queensland's humid air (leading to swelling, warping, mould growth, and eventual rot), steel is completely unaffected by atmospheric humidity. Steel doesn't absorb water, doesn't swell or shrink with humidity changes, and provides no food source for mould or fungus.

This moisture resistance is particularly important during the construction phase—timber frames exposed to Queensland's frequent rain during construction can absorb significant moisture that may not fully dry out for months or years, leading to ongoing problems with dimensional stability and potential mould issues.

Steel frames are unaffected by weather exposure during construction, so the frame you move into is exactly as manufactured—dry, straight, and ready to perform for decades without moisture-related deterioration.

For coastal Queensland homeowners, TRUECORE® steel provides confidence that your home's structure will withstand our challenging climate without the deterioration, pest problems, and maintenance issues that plague timber-framed homes.

Is steel framing suitable for two or three storey homes and extensions ?

Absolutely—in fact, steel framing is particularly well-suited to two-storey construction and multi-level homes. TRUECORE® steel's high strength-to-weight ratio means it can easily support the loads imposed by upper floors without requiring oversized members or additional support walls.

This structural efficiency translates to design freedom—we can create open-plan living spaces on the ground floor without a forest of support columns, and we can cantilever upper floor elements for dramatic architectural effects that would be difficult or impossible with timber framing.

Steel's dimensional stability is particularly important in two-storey construction. When the lower floor frame is supporting upper floor loads, any movement, warping, or compression of the framing members can cause problems with door and window operation, cracks in linings, and uneven floors.

Timber frames in two-storey homes are particularly prone to settlement and movement as the timber gradually compresses under load and continues to dry out after construction.

Steel frames don't compress, shrink, or change dimensions under load, so your two-storey home will maintain its structural geometry and performance long-term. For extensions and additions to existing homes, steel framing offers significant advantages. Because steel members can span longer distances with smaller section sizes, we can often add extensions without requiring extensive foundation work or structural support for the existing building.

Steel framing also makes it easier to match new work to existing building levels and alignments because of its precision and adjustability.

Whether you're building a new two-storey home or planning a future extension, TRUECORE® steel provides the structural performance, design flexibility, and long-term reliability that multi-level construction demands.

What maintenance is required for a steel framed home?

One of the most attractive features of TRUECORE® steel framing is that it requires essentially zero maintenance throughout the life of your home.

Unlike timber framing, which may require treatment for termites, replacement of rotted members, repairs to warped or twisted studs, or treatment for fungal growth or insect damage, steel framing is maintenance-free.

The protective coating on TRUECORE® steel is designed to last for the design life of the building without any maintenance or reapplication. You don't need to paint it, treat it, inspect it for pests, or worry about deterioration.

The steel is protected from corrosion by its metallurgically bonded coating, and because it's hidden within your walls, it's not subject to UV degradation, physical damage, or weathering. What does this mean in practical terms? Lower lifetime costs, less disruption to your home and lifestyle, and peace of mind that your home's structure will perform as designed for decades without intervention.

You'll never need to arrange access for termite inspectors to examine your frame, never need to budget for pest treatments or barrier renewals, and never face the anxiety of wondering whether termites or rot are silently compromising your home's structure. Your maintenance efforts can be focused on the cosmetic and functional aspects of your home—painting, landscaping, appliance replacement—rather than fundamental structural concerns. For busy families, this maintenance-free performance is invaluable.

You can focus on living in and enjoying your home rather than constantly maintaining its structure.

And when it comes time to sell, you can honestly tell potential buyers that your home has a steel frame that's as good as the day it was installed, with decades of trouble-free performance still ahead.

Ready to Build with the Best?

Contact The Markon Group or Call our head of sales Rob Quinn for a no obligation friendly chat 0436 002 012 today to discuss how we can use TRUECORE® steel to build your dream home in Brisbane.